Optimized processes, security, and global collaboration in the product lifecycle

How can companies efficiently manage their data and documents? How can they provide information across departments, locations, and organizations?

Even in individual projects, the number of documents quickly grows into the hundreds or thousands. Managing this data on network drives or email systems leads to bottlenecks in the face of the complexity of product development. Companies need a document logistics system that creates clarity and fosters teamwork.

Software for Product Lifecycle Management (PLM) is ideal for this task. Cloud-based systems, in particular, make document management more efficient by integrating all workflows and information throughout the entire product lifecycle. In this blog post, we explore how Cloud PLM systems simplify document management.

What are the benefits of cloud-based document storage?

Managing documents via the cloud offers two significant advantages:

Firstly, it promotes global real-time collaboration. Teams around the world can access legally binding documents and work on them together, significantly reducing development times.

Secondly, companies are not solely responsible for the security of their systems. Cloud providers must undergo rigorous certifications and audits, meeting the highest security standards. Sensitive information is optimally protected through data encryption, access controls, and regular security updates. This also simplifies compliance with regulations such as ISO and GDPR for customers.

What are the advantages of document management in PLM systems?

1. Centralized data storage:

The document management feature allows for company-wide organization of documents, promoting teamwork and knowledge sharing. Product-relevant documents, such as CAD files, are managed in a central location, avoiding data redundancies and ensuring all departments have access to up-to-date information.

2. Version control and change tracking:

PLM systems enable document versioning, ensuring teams always work with the latest data, as every change is logged.

3. Workflow and approval processes:

Integrated workflows automate approval and release processes, speeding up decision-making and ensuring structured processes without manual intervention.

4. Access controls:

Access rights can be clearly defined and managed within a PLM system, ensuring only authorized individuals can access sensitive documents.

5. Compliance adherence:

PLM systems provide audit-proof storage to meet regulatory requirements and industry standards (e.g., ISO).

6. Integrated data and processes:

Document management is often closely linked to areas such as project management, quality control, or product development. PLM systems integrate all product-related processes for comprehensive management.

7. Cost savings and increased efficiency:

With document management functions, employees use their working time more effectively, reducing search times and avoiding errors caused by outdated information. Improved collaboration across teams lowers costs in the long term, while automated processes enable faster turnaround times.

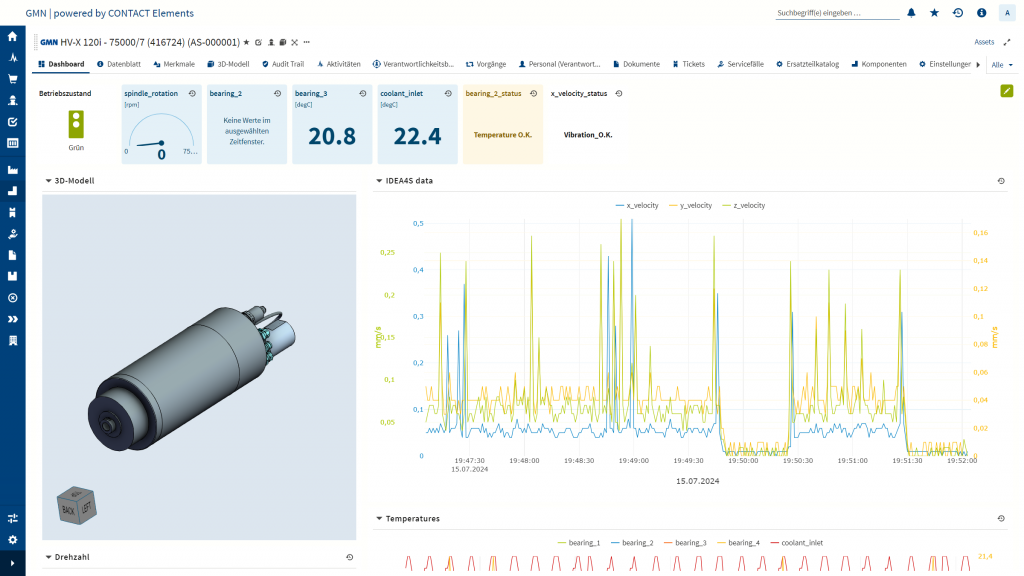

What makes document management with CIM Database Cloud stand out?

The intelligent document logistics of CIM Database Cloud enables organizations to maintain clarity and enhance collaboration even in complex processes. A powerful full-text search speeds up document retrieval and simplifies access to vital information.

With seamless integration with Microsoft Office for the web™, employees can use familiar applications to create, edit, and share documents without separate storage. Files are managed in the Cloud PLM document storage, allowing multiple people to work on the same document simultaneously—without requiring local MS Office installations.

Conclusion

Cloud PLM systems offer a powerful, secure solution for document management. Features like version control, workflow automation, and robust security measures help manage documents efficiently. Companies minimize risks and ensure compliance while the cloud-based structure offers maximum flexibility—teams can collaborate anytime, anywhere.

Learn more about how CONTACT CIM Database Cloud can optimize your document management.