Factors and features improving usability

In an increasingly digitalized world, cloud-based solutions for Product Lifecycle Management (PLM) play a crucial role in efficiently managing product data and processes. A number of providers develop Cloud PLM software. Apart from functionalities and pricing, the user experience (UX) holds particular importance as it significantly influences user acceptance.

In this blog post, you will learn why selecting user-friendly Cloud PLM software is essential and what considerations you should keep in mind.

Why UX is important

When it comes to software, a well-designed user experience is not just a nice-to-have but a crucial factor that significantly influences how users perceive a tool, adapt and use it. Here are 5 reasons why you should prioritize user-friendliness when choosing Cloud PLM software:

- User satisfaction: A well-conceived user experience increases user satisfaction. When users intuitively understand a software and find interacting with it pleasant and rewarding, they are more inclined to use it again.

- Efficiency and productivity: A compelling user interface and meaningful interaction options enable users to complete tasks faster and more effectively.

- Error reduction: A thoughtful UX helps minimize errors. Clear instructions, easy navigation, and consistent design elements lead to users making fewer mistakes and finding solutions faster when errors do occur.

- Accessibility: A good UX takes into account the diversity of the user base and includes people with different abilities and limitations. Accessible designs allow everybody to work with the software without barriers.

- Cost-Efficiency: Software with an intuitive UX can save costs in the long run, as users make fewer mistakes and the need for support and training decreases.

Cloud PLM and the challenges of user-friendliness

Cloud PLM systems enable centralized management of product information in real time, promoting collaboration and efficiency. Nevertheless, they initially pose some challenges for new users: they have to familiarize themselves with a new user interface, learn how to use complex functions, and handle data from a variety of sources. A sophisticated UX helps overcome these challenges:

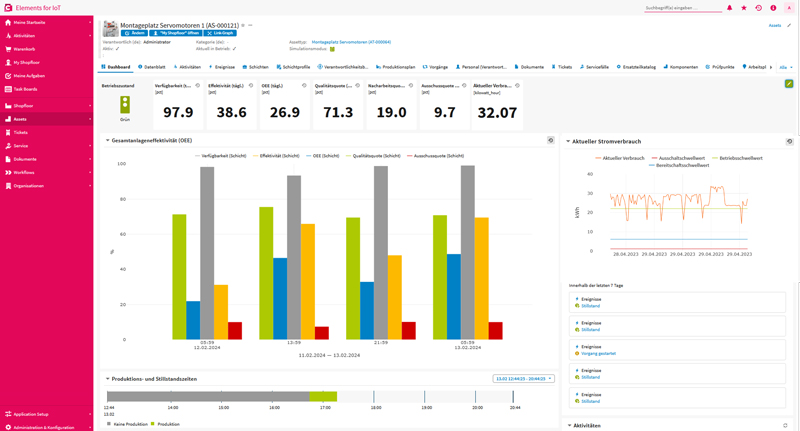

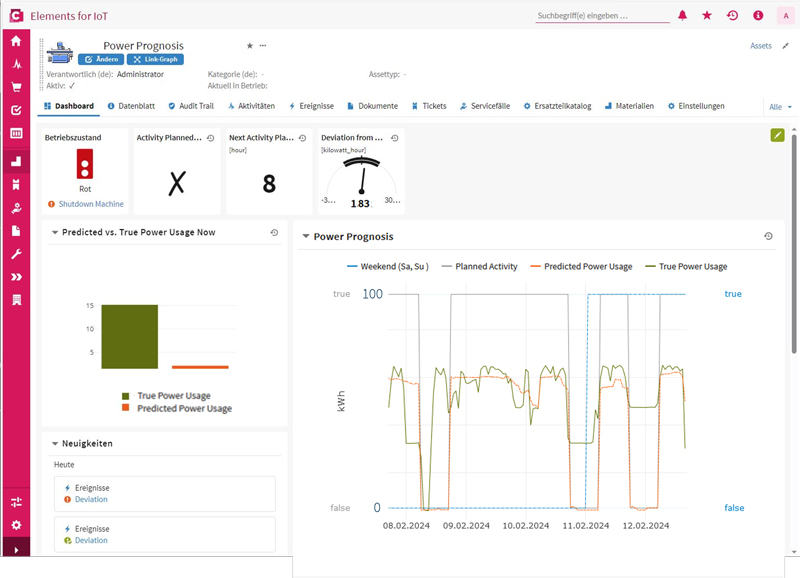

Intuitive user interface: The user interface should be simple and intuitive to enable quick familiarization. A clean design and well-placed features help users navigate easily.

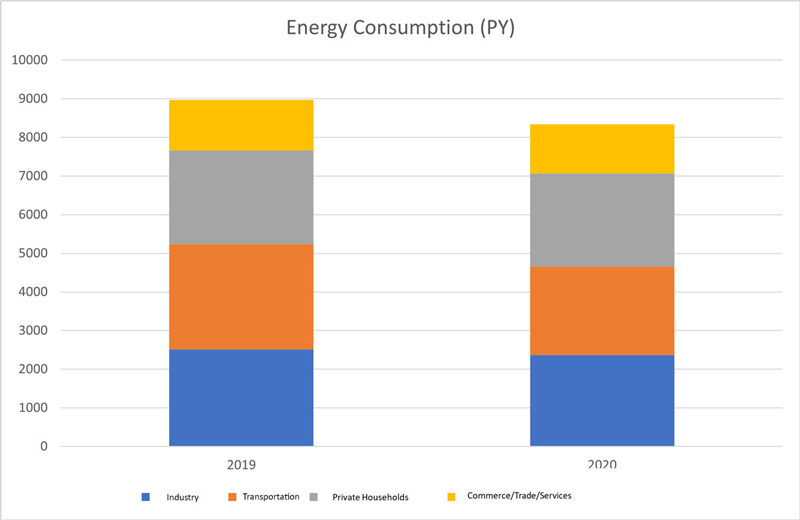

Customized dashboards & charts: Custom dashboards and time schedules allow users to see information and functions relevant for their tasks at a glance. Gantt charts, for example, provide a clear overview of project progress, aid in identifying task dependencies, and simplify resource planning.

Collaboration tools: A high-quality Cloud PLM platform should offer seamless collaboration features. Comment functions, real-time collaboration, and shared editing options are crucial for facilitating communication and information exchange.

Search and filter functions: Efficient search and filter functions, including an enterprise search, help users quickly access needed information. This is especially crucial with large datasets.

Integration with other systems: Seamless integration with other enterprise systems like ERP or CAD dissolves data silos and ensures all relevant data are linked.

User guidance and training: Well-structured tutorials and training materials assist users in utilizing the software to its full potential. A carefully crafted onboarding strategy is crucial to achieve a flat learning curve.

Feedback mechanisms: Users should be able to provide feedback for continuous software improvement. A dedicated community serves as an ideal platform for an open dialogue between developers and users.

Conclusion

For Cloud PLM software, an excellent user experience is not an option but a necessity. It enhances productivity, cost-efficiency, and user satisfaction. The entire team, including members with disabilities, can effortlessly and efficiently work with the tool. User-friendly Cloud PLM systems offer intuitive interfaces, customizable dashboards, collaboration tools, search and filter functions, training and feedback options, as well as integrations with third-party systems.

CIM Database Cloud provides state-of-the-art PLM features combined with an intuitive user interface and a flat learning curve.