Challenges and best practices for successful data migration

More and more companies are adopting cloud-based PLM systems to streamline their product development processes. Whether they are already using an on-premises PLM system and want to switch to a cloud solution or implementing a Cloud PLM system for the first time, one of the biggest challenges is the smooth and secure data migration.

How can this data be reliably transferred to the new system? In this blog post, we examine the challenges and best practices for successful data migration to Cloud PLM systems and offer tips on ensuring a smooth transition without data loss.

What challenges arise during data migration to Cloud PLM systems?

Migrating data to Cloud PLM systems, obstacles can present hurdles that complicate and delay the entire process:

- Data quality and consistency

Legacy data is often incomplete or inconsistent. Missing attributes, invalid values, or duplicate records can hinder the migration process. Particularly with CAD models, missing files or broken references may prevent models from being imported completely - Data scope and complexity

Depending on the scope and complexity of the data being transferred, the migration process can be very time-consuming. Large datasets, such as entire version histories of CAD data or multi-level BOMs, require significant computing resources and can slow down the migration. - Structural differences between systems

Data structures in the new Cloud PLM system may differ from those in your legacy system. Attributes, data fields, or relationships between records may be organized differently, requiring data transformation or restructuring before import. - Technical challenges

Migrating data to a Cloud system brings specific technical issues. For example, along with ensuring file format compatibility, sufficient network bandwidth and data transfer rates must be guaranteed. - Security and compliance requirements

Strict security and compliance regulations must be followed when transferring sensitive data to the Cloud. Data must be encrypted during transport and storage, and data protection laws such as GDPR must be adhered to.

What key questions should you address before data migration?

Data migration is often underestimated, although it is one of the most critical tasks before a new PLM system goes live. You should address several key questions early to import your legacy data successfully.

First, determine which data objects will be transferred to the new system: Are you migrating CAD assemblies, parts and BOMs, office documents, or projects? It’s also essential to define the scope of the data: Do you want to migrate data from a specific project, a product, a specific company location, or the entire data archive?

You should also decide how much historical data you want to migrate. Do you want to transfer only the latest version or all versions, including the complete audit trail and engineering changes? These aspects are crucial as they influence the scope and complexity of the migration.

You should also carefully examine the content of the data itself. Consider whether all attribute values and CAD parameters are needed or if it’s sufficient to import only some of them. This is important to define which data should be stored in which objects and attributes in the target PLM system.

What makes data transfer with CIM Database Cloud so simple?

- User-friendly import tools

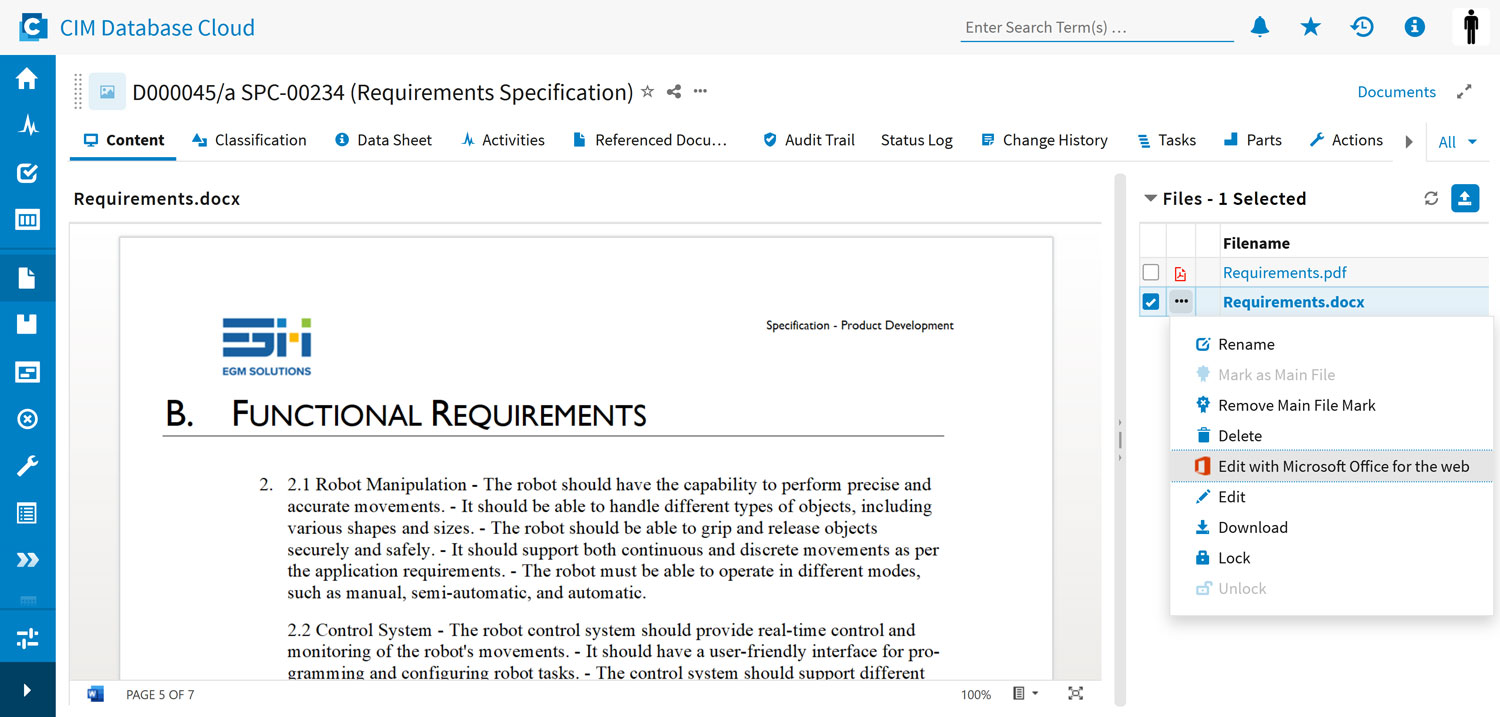

The cloud-based PLM system CIM Database Cloud offers powerful, easy-to-use import tools specifically designed to simplify the migration process. They allow you a quick and efficient import of configuration data such as field selection values (e.g., dropdown fields), as well as PLM data such as CAD documents, parts, BOMs, office documents, projects, and requirement specifications. - Support for various file formats

CIM Database Cloud supports a wide range of file formats and data sources, making it easy to import different data objects. These include Excel files, CAD formats, and the ReqIF format for requirement specifications. - Automated validation processes

CIM Database Cloud includes built-in validation mechanisms that help identify and correct potential errors during the import process. These functions automatically check whether the data is complete and consistent during import, contributing to high data quality. - Iterative Migration Approach

The platform supports an iterative migration approach, allowing you to import and test data step by step. This helps identify and resolve potential issues early on, without affecting the migration process. This approach reduces the risk of errors and accelerates data migration. - Comprehensive Documentation and Support

Alongside the migration process, CIM Database Cloud offers extensive documentation and tutorials. These contain clear instructions and examples on how to import and configure different data types. Additionally, customer success managers are available to assist if needed.

Conclusion

Data migration to cloud-based PLM systems is often fraught with many challenges. Successful data migration, therefore, requires careful planning, considering aspects such as data quality, scope, structural differences, and security requirements.

CIM Database Cloud enables you to efficiently migrate your PLM data and make your product development processes future-proof . With user-friendly import tools, support for various data formats, automated validation processes, and comprehensive documentation, companies can ensure the seamless and secure integration of their existing data. An iterative migration approach, combined with extensive preparation, minimizes risks and guarantees a smooth transition to the new system.